CNG Cylinder

Home > Products > CNG Cylinder > ISO11119 250 Bar CNG Glass Fiber Wrapped Cylinder

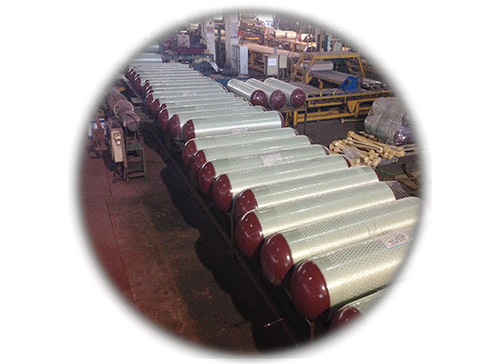

ISO11119 250 Bar CNG Glass Fiber Wrapped Cylinder

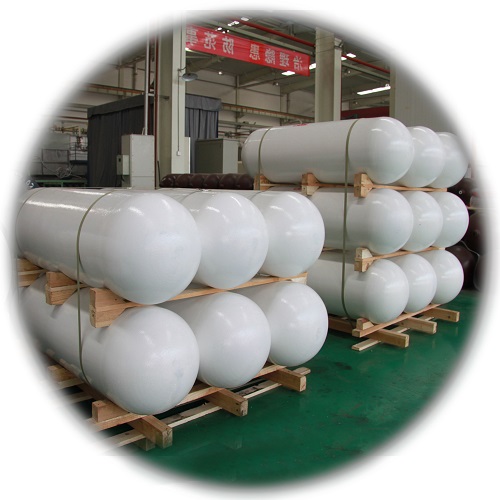

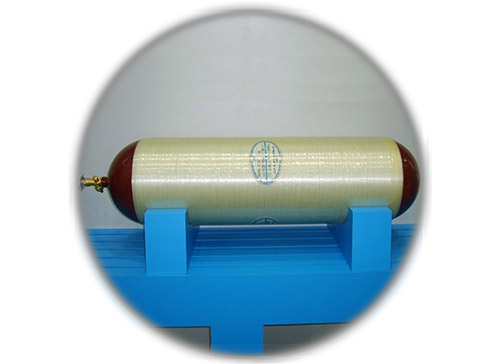

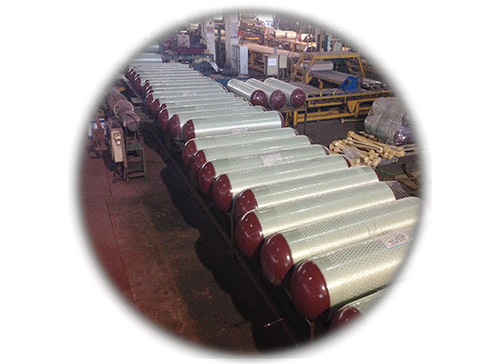

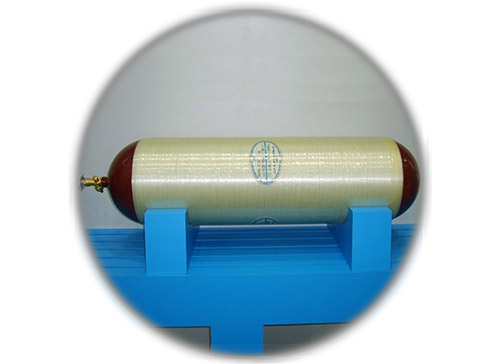

Our current ISO 11119 standard CNG cylinder is type 2 hoop wrapped cylinder with a load-sharing metal liner and composite reinforcement on the cylindrical portion only. It is designed for storage and conveyance of compressed natural gas (CNG). It is similar to ISO11439 type 2 CNG cylinder, but with working pressure 250 bar, and can be assembled into cascades and skids. The whole cascade and skid is mounted onto trucks, and the truck can run to transport CNG as gas transport module or go to different places and fill CNG as a mini mobile CNG filling station. The lifetime our cylinders can be minimum 15 years, and up to 20years.

We have more than 15 years manufacturing experience, and can design any kind of CNG cascade according to customers' requirements. Just advise your technical requirement and we will provide you the best CNG cascade solution.

How To Keep Our Cylinders Safe:

We do below to ensure excellent mechanical properties of the cylinders:

* Metal graphic test for each batch of steel tube

* First article test before each batch of cylinder starts heat treatment

* Different heat treatment temperature and time for different batch of steel tube and cylinders

We do below to eliminate leakages & other defects:

* Regular inspections & tests required by international standards

* 100% Cylinder bottom leakage test

* 100% Finished product leakage test

* Advanced digital threading machine

* Milling threading technique

* QC inspection after threading

We do below to eliminate cracks & wrinkles

* Cylinder bottom UT detection test

* Cylinder bottom thickness measurement

* 100% wrinkle inspection by endoscope

Specifications:

|

Model Number: |

CNG2-G-406-200-25B |

|

Diameter: |

Liner 406mm; Total with glass fiber wrap: 421mm |

|

Water Capacity: |

200L |

|

Length: |

1893mm Total with valve: 1991mm |

|

Weight: |

211.8kgs |

|

Manufacturing Standard: |

ISO11119-1:2012 |

|

Working Pressure: |

250 bar |

|

Hydraulic Test Pressure: |

375 bar |

|

Min. Design Burst Pressure: |

750 bar |

|

Life Time: |

15 years |

CNG Cylinder Steel Material Chemical Element Content (%):

|

C |

Si |

Mn |

Cr |

Mo |

P |

S |

P+S |

Cu |

|

0.26~0.34 |

0.17~0.37 |

0.4~0.7 |

0.8~1.1 |

0.15~0.25 |

≤0.02 |

≤0.02 |

≤0.03 |

≤0.2 |

CNG Cylinder Steel Material Mechanical Property Parameters:

|

Tensile Strength ( MPa ) |

Yield Strength ( MPa ) |

Y / T Ratio |

Elongation ( % ) |

Impact Strength ( J / cm2 ) (V-notch -50℃ Transverse Width: >5-7.5mm) |

|||

|

≥830 ≤950 |

≥705 |

≤0.92 |

≥14 |

Average |

≥ 35 |

Minimum |

≥ 28 |

Guarantee value of property of glass fiber wrapping layer:

|

Tensile Strength |

Inter-layer Shear Strength |

Glass Transition Temperature |

|

≥950MPa |

≥13.8MPa |

≥ 120℃ |

Applications:

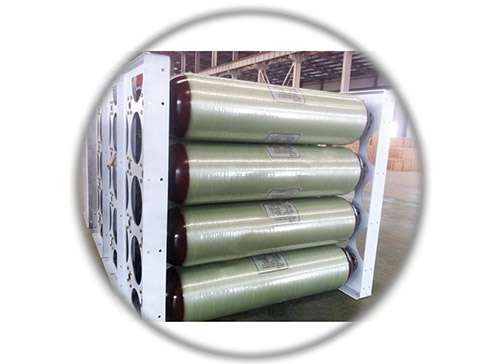

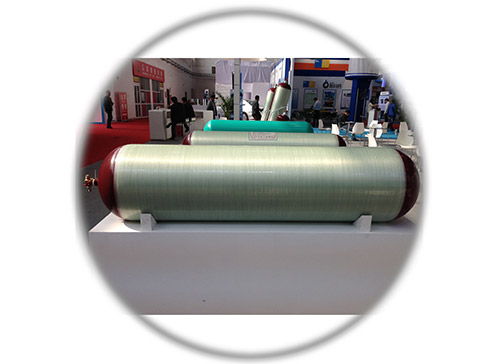

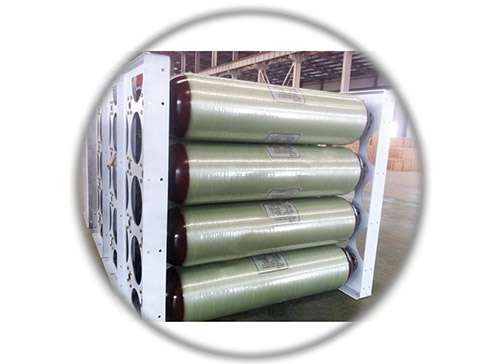

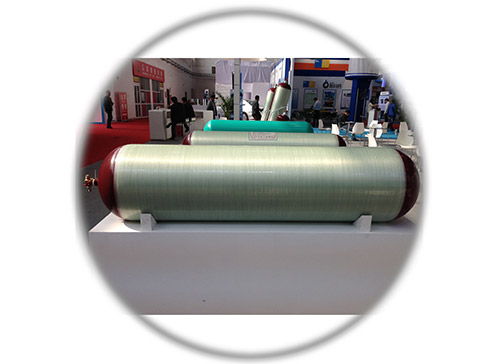

ISO11119 Standard CNG Composite cylinders are assembled into a CNG cylinder bundle or gas transportation module (GTM) to transport CNG:

Mobile CNG supply unit:

CNG gas transportation module used as mini movable gas filling station:

- Prev:ISO9809 250 Bar CNG Steel Cylinder

- Next:No Next